The first of the two new strand pelletizing systems type ips-SGA 220/2 delivered has gone into operation at ENNEATECH AG in Großefehn, East Frisia.

ENNEATECH places its faith in automated ips strand pelletizing systems

Niedernberg, 28.10.2019. For the production of high-quality polyamide pellets, ENNEATECH AG which is based in the East Frisian town of Großefehn, has now commissioned the first of two automated strand pelletizing systems from ips Intelligent Pelletizing Solutions GmbH & Co KG. The company is replacing its conventional systems in order to operate more productively, more economically and more profitably.

ENNEATECH AG specialises in the production of technical plastics and plastic pellets and is among the leading polymer specialists on the European market. The company’s premium and innovative plastics are in use around the world. “A special feature of our products is that we use raw materials with a past to produce plastics for the future. We utilise primarily synthetic fibres which occur as a byproduct in the high-end textile industry. By using, or rather recycling, these sustainable raw materials, we make a meaningful contribution to reducing climate-damaging carbon emissions,” explains Hartmut Schoon, Executive Board Member at ENNEATECH AG.

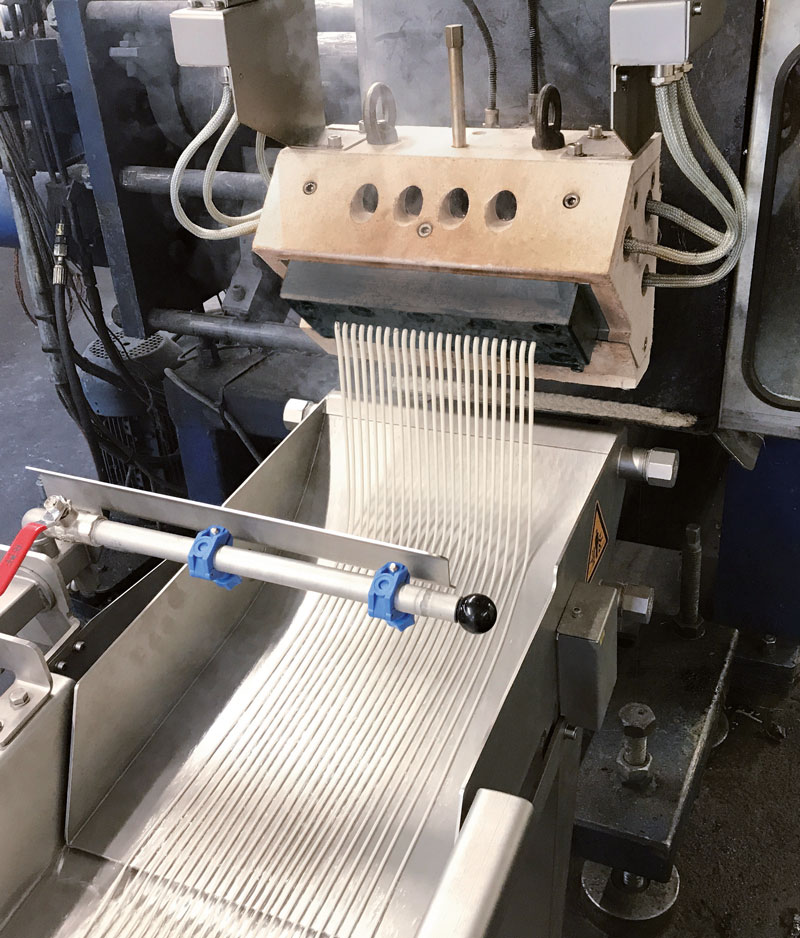

The two modern automated strand pelletizing systems of the type ips-SGA 220/2 – each including an ips-SGK 220 strand die head – are particularly intended by the East Frisian plastics manufacturer for the production of PA 6.6. and PA 6-compounds. In addition, one of the two systems was fitted with an ips-PWS 100 A process water system. The second plant can accommodate a process water system already in use in the company. “Above all, the flexibility of ips and, of course, the sophisticated technology of the system itself, were what convinced us,” explains ENNEATECH Production Manager, Artur Lange. “As a result of the simple start-up of the pelletizing process and the automatic re-threading after strand breakage, in particular, we have a significant saving in time, staffing levels and, as a result, costs.”

“The ips system is perfect for compounding and for the recycling of technical plastics, in particularly also for the polyamide-synthetic fibres used as a raw material by ENNEATECH,” explains ips owner and managing director, Gerald Weis. Each of the systems can achieve throughput of up to 1,200 kg per hour, depending on application and polymer. Thanks to the central user interface, the system is easy to operate and control. The cooling section prior to cutting in water and air can be individually adapted to the specific product. The integrated strand suction device ensures dry pellets.

As far back as 2016, ENNEATECH was using an ips-SG 320/D strand pelletizer. “Even then, we were impressed by the fast and focussed way in which ips responded to our customer wishes and requirements, and implemented them,” is how Hartmut Schoon explains the decision to go with ips once again. In addition to the proven expertise and the wealth of experience of the ips team, particularly in the compounding-, masterbatch- and recycling industries, ENNEATECH was won over by the good value-for-money, the prompt delivery of spare parts and the service and reachability.

Strand die head type ips-SGK 220

Obviously delighted with the newly-commissioned ips-SGA 220/2 from ips Intelligent Pelletizing Solutions GmbH & Co. KG: Hartmut Schoon (left), Executive Board Member, and Artur Lange, Production Manager at ENNEATECH AG.