The ips LFT-system is suitable for the production of a wide range of materials with different fibre reinforcement, defined pellet length and different polymers. LFT pellets with fibre contents of between 30 and 60 wt% and throughputs of up to 1,000 kg/h can thus be produced using the system. All common polymers can be used as melts, while glass, carbon and aramid fibres as well as hybrid combinations come into consideration as reinforcing fibres. The ips-LFT HP is available with up to 60 strands. The cut length of the strands can vary between 6 – 25 mm. The fibre lengths contained correspond exactly to the cut length of the pellets.

Features

- Simple operation with high system safety

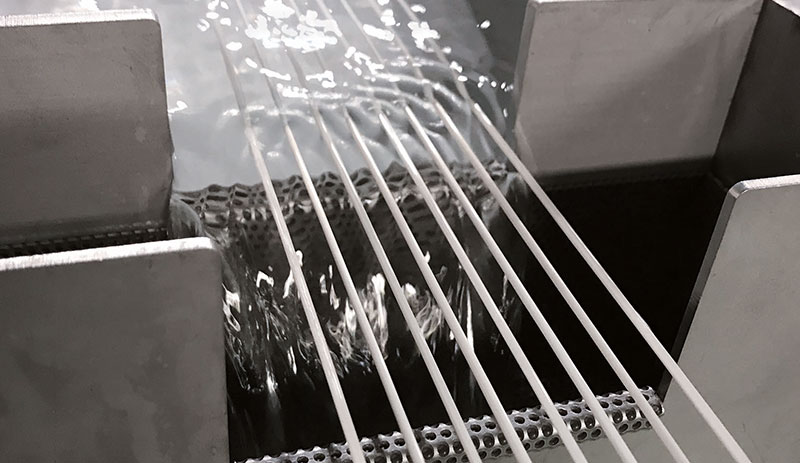

- Variable cooling section for the polymer strands before cutting

- High production yield thanks to short set-up time and downtime

- Minimum personnel required

- Central control of the entire line

- Controlled spreading process goes easy on the fibres

- Improved degree of impregnation at increased process speeds

- Monitoring of heating zones with indication of where defective heating elements are located

- Simple replacement of the die plates

Would you like to see the system in action? Our 8-strand pilot system is available for customer trials, in order to try out individual product requirements and produce small quantities for test purposes.