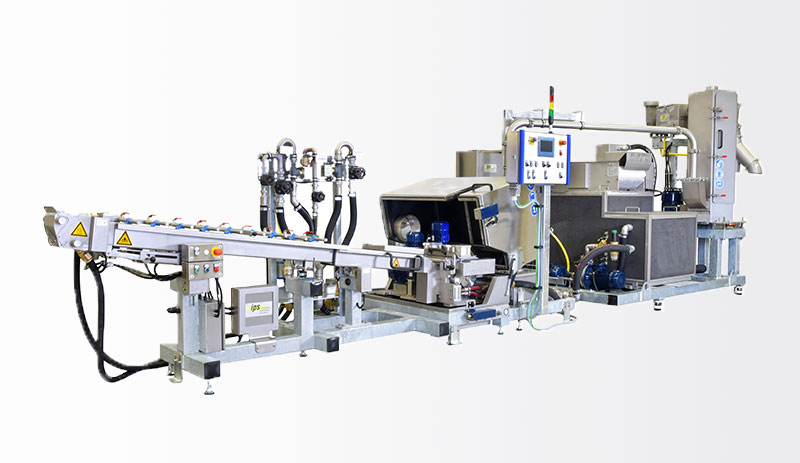

Underwater strand pelletizing system type ips-SGU/2 are used especially for processing recycled materials. Their sturdy design, sealed bearing points in the cutting head, straightforward operation and fast maintenance thanks to easy access to all components guarantee high process reliability. System operation can be adapted quickly and flexibly to changed operating parameters at any time.

The result: outstanding pellet quality with high process stability.

On account of the modular design, the underwater strand pelletizing system can be configured into a complete pelletizing system – according to your individual requirements. We offer you tailor-made pelletizing solutions for your requirements, from the agglomerate catcher through an after-cooling section with solids feed pump and pellet dryer through to process water system and complete control through the ergonomic ips operator guide.

Features

- Working widths of 120 mm, 220 mm, 320 mm or 420 mm

- Draw in speeds up to 250 m/min

- Cooling sections up to 8 m before cutting

- Throughputs up to 4,300 kg/h

- Particularly easy start of the pelletizing process

- Fully automatic re-threading after strand breakages thanks to special design of the start-up head

- Low-dust, even pellets

- High production yields

- Extremely easy operation, minimum personnel requirements

- Sound insulation as standard

- Optimum design of the cutting area to prevent deposits