Niedernberg, 14.01.2020. As of 1 January, 2020 the next generation has joined the management board at ips Intelligent Pelletizing Solutions GmbH & Co. KG. Alongside the founder, Gerald Weis, his sons Julian and Simon are now also responsible for the management of the company.

Niedernberg, 28.10.2019. For the production of high-quality polyamide pellets, ENNEATECH AG which is based in the East Frisian town of Großefehn, has now commissioned the first of two automated strand pelletizing systems from ips Intelligent Pelletizing Solutions GmbH & Co KG. The company is replacing its conventional systems in order to operate more productively, more economically and more profitably.

Niedernberg, 23.05.2019. In addition to strand pelletizing, ips Intelligent Pelletizing Solutions GmbH & Co. KG has also established a solid standing in the market with underwater pelletizing systems. Since the launch of this type of system in 2016, ips has already sold a number of ips-UWG 75 S underwater pelletizing systems. Now, towards the middle of the current year, the first ips-UWG 120 S system for throughputs of up to 2,500 kg per hour is to be commissioned at the premises of an extrusion profile producer in Italy.

Niedernberg, 12.04.2019. For higher process automation and in order to be able to process more complex products, Recoplast AG (Gretzenbach) is staking on an automated strand pelletizing system from ips Intelligent Pelletizing Solutions GmbH & Co KG. The type ips-SGA 120/2 system has now started operation with the Swiss recycler.

Niedernberg, 05.11.2018. Instead of big anniversary celebrations on the occasion of their 20th jubilee, ips Intelligent Pelletizing Solutions GmbH & Co. KG decided to support St. Cyriakus Kindergarten with a EUR 5,000 donation.

“Our pelletizing systems are in use all around the world, but since 2014 Niedernberg has been home to ips,” says Gerald Weis, owner and Managing Director of. “And, as we feel very much at home here, my team and I are eager to support a local institution on the company’s 20th birthday.” As a company with a future-oriented approach, we soon decided on St. Cyriakus Kindergarten. “Because children are our future,” declares Gerald Weis, whose two sons have also been working in the company for some time now. This news was received with great delight by both children and teachers and the representative of the supporting agency, Rev. Ernst Haas. As a rule, money for special investments is in short supply.

The kindergarten’s wish list has long featured a water play area. “As an element, water is very special for the children and offers numerous fundamental experience opportunities. Using simply experiments, exciting water-related phenomena can be researched and experienced,” is how Silke Elbert, Director of the kindergarten explains the significance of a play area of this kind for the children’s development.

“For us as a community, good cooperation among the local population and the companies and institutions located here is very important. The involvement of companies like, in this case, ips with Niedernberg, demonstrates their interest in the town in which they are located and a great sense of responsibility, and promotes the community spirit which benefits everyone,” says Niedernberg’s delighted mayor, Jürgen Reinhard.

Niedernberg, 29.10.2018. This year, ips Intelligent Pelletizing Solutions GmbH & Co. KG in Niedernberg is celebrating 20 years in existence. Set up in 1998, ips’s proven expertise makes the company an all-in-one specialist, innovative leader and competent advisor when it comes to strand pelletizing and underwater pelletizing.

ips Intelligent Pelletizing Solutions GmbH & Co. KG regards itself as the consistent further development of a manufactory. Just why this is so, and how it is implemented in the company, was explained by Managing Director Gerald Weis in an interview with K-ZEITUNG.

Niedernberg, 17.09.2018. Intelligent Pelletizing Solutions GmbH & Co. KG in Niederberg/Germany recently extended its range of customised strand pelletizing systems by underwater pelletizing systems. The first two systems of the type ips-UWG 75 S have now been put into operation at “Delta Kunststoffe AG” in Weeze on the Lower Rhine.

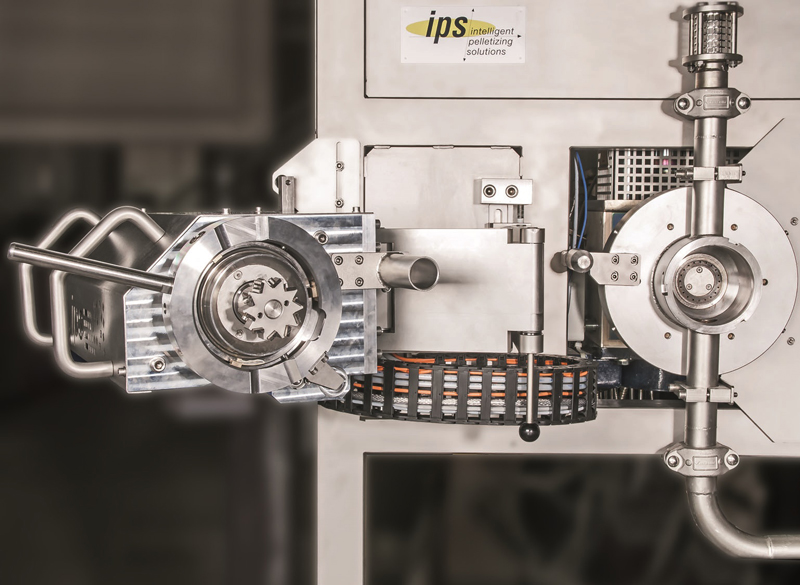

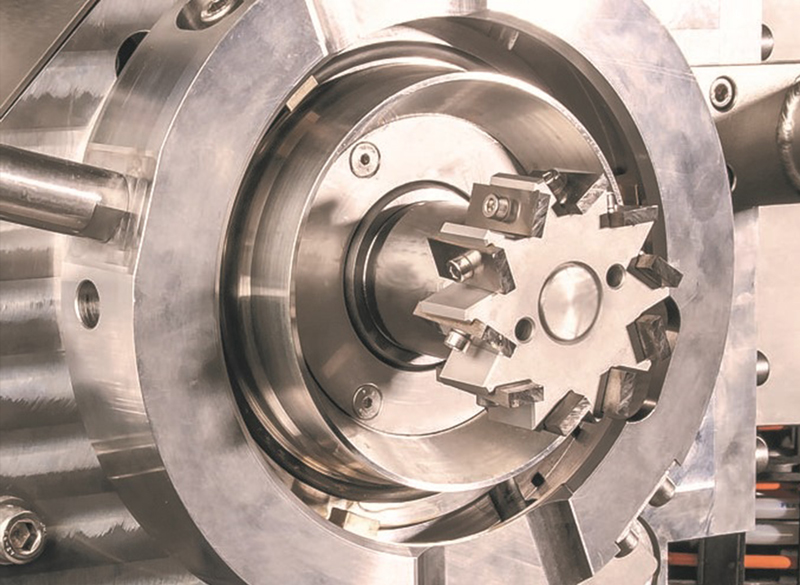

Delta Kunststoffe AG specialises in colour master batches, electrically conductive plastics, additive batches and special compounds. As an experienced compound contract manufacturer, Delta also produces respective products in accordance with customer specifications. The independent compound manufacturer already uses several conventional strand pelletizing systems from ips for its product range. “The innovative approach of the ips underwater pelletizing systems such as the pelletizer’s swivel system or the simple change of the cutter hub had us convinced. And the extremely clear layout and user-friendliness of the control design is a great boost for our machine operators. Another important aspect for us is that ips took the user-specific demands we make on the machine into consideration without restrictions and implemented these,” says Manfred Fiedler, Operations Manager at Delta Kunststoffe AG, explaining why the company chose ips once again.

The ips-UWG 75 S is suitable for the production of spherical pellets of thermoplastic material in raw material production, the master batch and compounding industry and for recycling plants. ips not only supplies the actual pelletizing unit, it provides the complete pelletizing system, comprising melt pump, screen changer, start-up valve, die plate with pelletizing unit, process water system and pellet dryer.

“From individual components through to complete solutions, the modular design of our systems both for strand pelletizing and for underwater pelletizing offer our customers a huge degree of flexibility. Customers get exactly the system they need,” explains Gerald Weis, owner and managing director of ips.

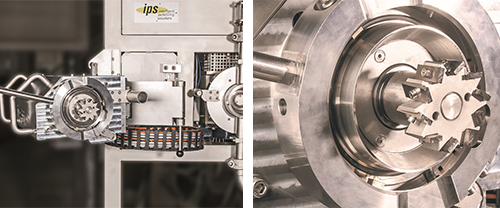

Fig. 1 Pelletizing unit with swivel system

Fig. 2 Simple change of the cutter hub

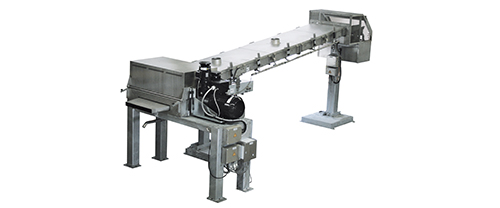

Niedernberg/Germany, 13.08. 2018. Niedernberg-based ips Intelligent Pelletizing Solutions GmbH & Co. KG is delivering four underwater strand pelletizing systems of the type HJCH9 with a working width of 900 mm to a German customer. Each of the systems will be supplemented by a strand die head of the type ips-SGK 720 – now with an automatic scraping device developed by ips as a brand new feature.

ips has now produced and sold machines of this magnitude for the first time. The pelletizing specialist purchased the underwater strand pelletizing systems from his South-Korean partner Han Jin Ind. Co. Ltd. for this. They were re-engineered, completed and meet all the requirements of the CE standard. Thanks to the large working width, the systems can process up to six tonnes of polycarbonate per hour into cylindrical pellets.

The underwater strand pelletizing systems have each been supplemented by a strand die head for which ips has developed and constructed an automatic scraping device. It has been registered as a utility model with the German Patent and Trademark Office and entered in the register accordingly.

Together with Han Jin, ips supplies complete underwater pelletizing systems including the necessary peripheral equipment up to a working width of 1,200 mm and a maximum throughput of 18 tonnes per hour.

Niedernberg, 03.07.2018. As of 1 July 2018, Julian Weis is taking over the newly-created position of Project Manager at ips Intelligent Pelletizing Solutions GmbH & Co. KG in Niedernberg.

In his role as Project Manager, Julian Weis will be the interface between ips and its customers. He will look after internal and external coordination of all customer orders – from incoming order to final acceptance of the machinery, including follow-up – and will be the contact partner for all those involved. He will bear responsibility for ensuring compliance with budgets, schedules and quality standards.

Julian Weis successfully completed his studies at Darmstadt University of Applied Sciences in 2017, graduating with a Master’s Degree in Engineering, specialising in Plastics Technology. The 30-year-old then spent three years with Autoneum Germany GmbH, working as a process engineer on the support and optimisation of production systems and components.

Following his brother Simon, who joined the company in 2017, Julian Weis is a further member of the next generation to join owner-run ips. “There is something special about both sons following in their father’s footsteps, pursuing and advancing ips’ successfully adopted course as specialist for pelletizing plant and systems,” says delighted Managing Director and father Gerald Weis.

Our complete contact page incl. all our representations abroad can be found here:

ips

Intelligent Pelletizing Solutions GmbH & Co KG

By using our contact form you agree to our data protection regulations.

To combat spam requests, we use Google ReCaptcha technology, for example.

By using our contact form, your IP address will be transmitted to Google.