Niedernberg, 09.02.2018.

In December 2017, the 1000th system left the production hall at ips Intelligent Pelletizing Solutions GmbH & Co. KG (Niedernberg near Aschaffenburg). The ips-SGU 120/2 HS, a highly innovative underwater strand pelletizing system, will start operation in the 1st quarter of 2018 at Märkische Faser GmbH in Premnitz. With it, high-quality plastic pellets are to be produced from polyethylene terephthalate (PET) residues.

Niedernberg, 30.06.2017. As of 1 July, 2017, Simon Weis is joining the team as Product Manager for underwater pelletizing systems at ips Intelligent Pelletizing Solutions GmbH & Co. KG in Niedernberg.

Simon Weis successfully completed his studies at Darmstadt University of Applied Sciences in 2013 with a Master’s Degree in Engineering, specialising in Plastics Technology. Following graduation, the 27-year-old spent four years working in the area of applications engineering with a Swiss polymer manufacturer.

In the newly-created position, Simon Weis will be responsible for ips underwater pelletizing systems worldwide. He will look after both further technical advancement and the development of new markets for these systems.

Simon Weis is the first of the next generation to take his place in the owner-run company. “I am very proud that my son will be supporting our team with his expertise, and further advancing the success story of ips as a specialist for pelletizing plant and systems,” says delighted Managing Partner, Gerald Weis.

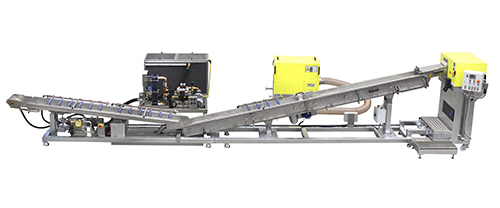

Niedernberg, 10.05.2017. ips Intelligent Pelletizing Solutions GmbH & Co. KG has further added to the machinery in its technical centre at the Niedernberg location. In addition to an underwater pelletizing system ips-UWG 75 S and a number of conventional strand pelletizing lines, the automatic strand pelletizing system ips-SGA 220/2 is now also available for internal development trials and customer trials.

Shorter refitting times and ergonomically optimised work sequence.

For integration into changing downstream devices, a height-variable pelletizer substructure has been developed on the basis of the tried and tested strand pelletizer type ips-SG/ D.

In the development of the new strand cooling trough type ips-SKW 600/900, the constructors at ips, Niedernberg, paid particular attention to simple and secure operation and also to a displacement mechanism insensitive to contamination. The horizontal displacement mechanism has been integrated into the substructure of the strand cooling trough. It enables a fast, controlled approach and removal process by one-hand operation and thus reduces the downtimes.

Compared with other displacement mechanisms customary on the market, such as rail and roller systems, the trough is displaced by a lever, which can easily be accessed. As a result of its favourable transmission ratio, fast and easy displacement of the trough is possible. The ips displacement system has been registered for a utility model.

ips strand cooling troughs are particularly robust systems for flexible use. The troughs are manufactured in various widths and lengths to match the processes. The fitting variants range from height-adjustable strand cooling troughs via ones with integrated process water systems through to strand cooling troughs for the pharmaceutical area.

The cooling troughs have been equipped with adjustable strand guide rollers of stainless steel or plastic, strand breakage monitoring or with directly connected strand dewatering units.

ips Intelligent Pelletizing Solutions GmbH & Co. KG is expanding its product range with the addition of underwater pelletizing systems (UWG-S). With types ips-UWG 75 S and ips-UWG 120 S the manufacturer of pelletizing systems and components is now also offering systems for the underwater pelletizing of all thermoplastic polymers.

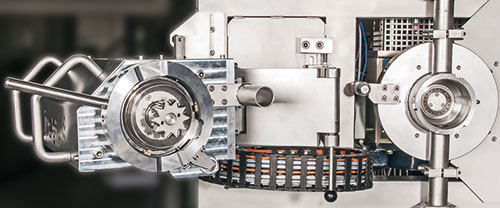

In the strand pelletizer type ips-SG/D, the tried and tested ips cutting head has been provided with a direct drive of the cutting rotor. Combined with a driven upper feed roller, which guarantees an optimum feed of the strands to the cutting device, this is an innovation in strand pelletizing technology. In addition, this finish improves the strand quality to be achieved and makes very high torques and cutting forces possible, as are necessary in production of compounds.

The strand conveyor type ips-SFB with motor-driven height adjustment enables fast, flexible and user-friendly adaptation to changing process conditions. In combination with water and air cooling, even difficult materials can be worked on in a process-safe way. The stainless steel conveyor belt has been designed for a conveying speed of up to 140 m/min.. The strand conveyor type ips-SFB has been planned for connection to a strand cooling trough which already exists. As a result of the infinite angle and height adjustment, the strand conveyor can be operated within or above the strand cooling trough. An integrated process water system comprising a buffer container, process water pump and double filter unit for simple and fast connection to the strand cooling trough makes a self-enclosed process water circuit possible.

On 25 August, 2014, after just a 10-month construction period, ips Intelligent Pelletizing Solutions GmbH & Co. KG moved into the new administrative and production premises in Niedernberg near Aschaffenburg.

The new building with a total floor space of 1200 m² offers the best preconditions for the further expansion of the owner-managed German manufacturer of pelletizing systems.

The first milestone of ips’ expanded product portfolio will be the new underwater pelletizing system ips-UWG-S, which is to be launched at the end of 2015. At the same time, the new Technical Centre is to go into operation.

Our complete contact page incl. all our representations abroad can be found here:

ips

Intelligent Pelletizing Solutions GmbH & Co KG

By using our contact form you agree to our data protection regulations.

To combat spam requests, we use Google ReCaptcha technology, for example.

By using our contact form, your IP address will be transmitted to Google.